Inside 1923, Doctor. Richard Sellingman created the very first plate heat exchanger, and also forever revolutionised the entire process of indirect temperature transfer. Right now, these items are available in many houses, industrial establishments and production vegetation of numerous industries. Their built in style provide them with a distinct advantage over other sorts of heat exchangers, like covering and also pipe kinds, adiabatic steering wheel kinds, etc.

Positive aspects

Consider some of the different features of plate heat exchangers which make them arguably the very best gadgets for most temperature transfer apps.

Compactness. They will use skinny sheets of metal to move heat from liquid to another. These kinds of metallic plates are usually lined along with corrugations that provide all of them a big floor to get a very small volume. This provides these a really tiny type factor when compared with other types of heat exchangers, preserving valuable floor room you can use for other functions. It will be possible for it to offer the exact same thermal coefficient since what tubular type up to 5 times the dimensions. Almost all of the helpful in little properties, places of work, and producing crops that want all of the area they are able to acquire.

High Energy Efficiency. These people operate from increased winter efficiency than additional heat exchangers because of the large surface area from the dishes. The cooling and also heating liquid distributed on the discs, going for much more contact regarding temperature exchange. The actual thin chambers in between each plate also aim to increase the volume of fluid in contact with the particular steel plates.

Affordable. These exchangers are usually relatively simple and also cheaper to produce as compared to other styles. Because of their dimensions, they might require much less substance to make. Additionally they supply the maximum thermal ease of fairly low-cost. This makes these the most monetary choice for heat move duties.

Flexibility. They are very adaptable because they may be used in many programs with only minimum modifications. Of course, if adjustments should be utilized, they can be applied along with relative simplicity, ending the necessity to buy a brand new heat exchanger. In addition they focus on an array of fluids and therefore, make sure they are suitable for many industrial applications.

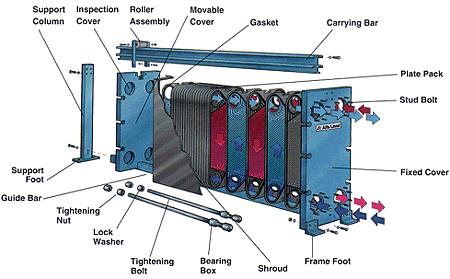

Simple Set up as well as Upkeep. They appear relatively comparable externally; as a result installation of brand new gadgets relatively easy together wouldn't normally concern yourself with incompatible gasket sizes, varying enter and also output valves as well as pipes, and so forth. Due to the right tools, these strong machines may also be an easy task to dismantle as well as take apart. This will make washing as well as other servicing tasks easier to execute.

Down sides

Leakage. Although the discs as well as gaskets in them tend to be closed tight, there is a greater prospect of loss compared to shell and conduit kinds heat exchangers. However so long as you will not run all of them beyond normal operating regions, 1 shouldn't get worried too much about this.

Temperatures Distinction.These people deal with fluids with small on track temperature variations. Nevertheless, it doesn't are well as any covering and pipe type heat exchanger regarding essential fluids along with massive differences in temperature.

In the end, the advantages of plate heat exchangers make sure they are well suited for basic heat exchange applications. Next time you need heat exchangers for your home, workplace, or business plants, try finding a plate heat exchanger?

check out our own web site http://www.ballardsgreatlakesgeothermal.com for more information about heat exchangers.

RSS Feed

RSS Feed